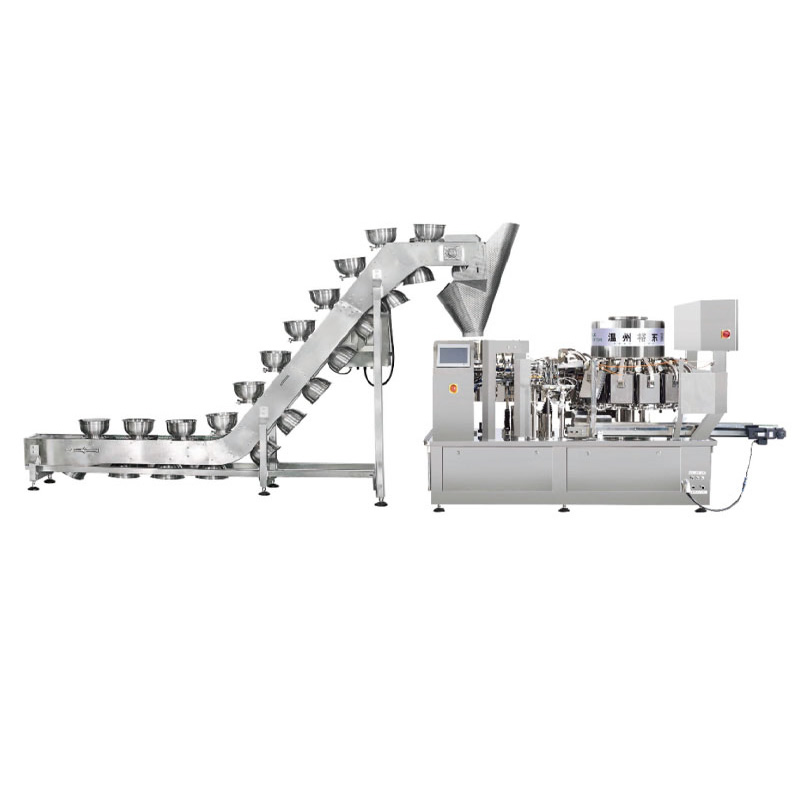

Automatic Bag Feeding Packaging Machine

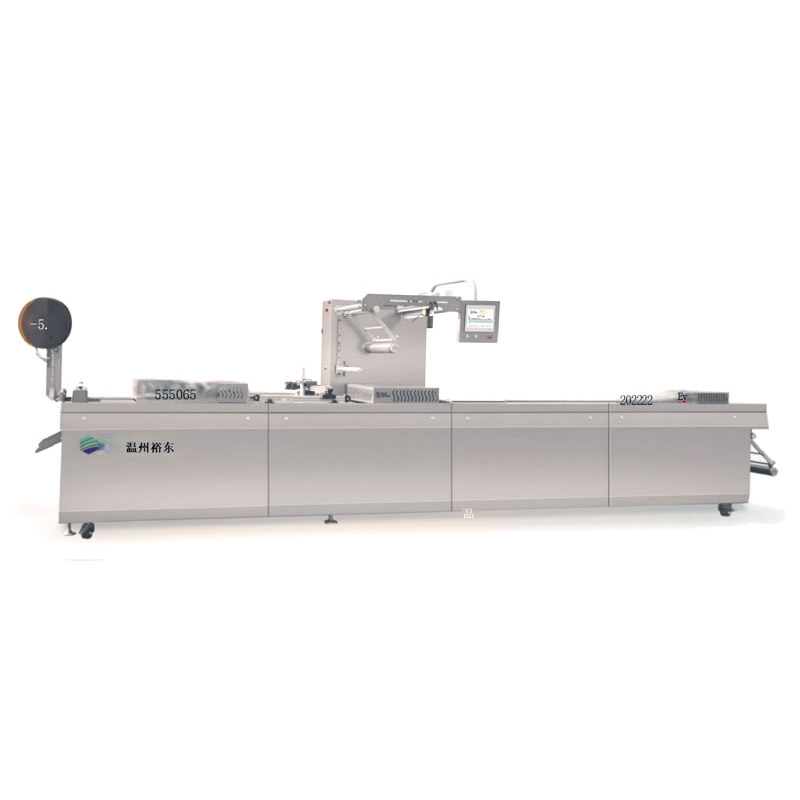

Automatic Vacuum Premade Pouch Machine

Automatic Vacuum Packaging Machine

Premade Vacuum Packaging Machine

Fully Automatic Rotary Vacuum Packing Machine

Automatic Vacuum Food Packaging Machine

Automatic Vacuum Food Packaging Production Line

Fully Automatic Vertical Packing Machine

High Speed Vertical Form Fill Seal Machine

Fully Automatic Vertical Form Fill Seal Packaging Machine

Large Size Auto Vertical Packing Machine

Automatic High-Speed Continuous Drawing Vacuum Packaging Machine

Automatic High-Speed Thermoforming Vacuum Packaging Machine

Professional automatic thermoforming machine manufacturer

Next, let's summarize the advantages and disadvantages of the bag-feeding vacuum packaging machine. The advantages of the bag-feeding vacuum packaging machine are reflected in the following aspects:

1. Save labor

Because the bag-feeding vacuum packaging machine uses a robot to automatically take bags, print dates, open bags, measure, drop materials, vacuumize, seal, and output products, there is no need for manual operation throughout the process, which saves the company's labor input and solves the problem of labor difficulties in today's society.

2. Improve production and packaging efficiency

Manual packaging also requires manual metering and bagging. If the manual packaging output is 3t per hour, the bag-feeding vacuum packaging machine can reach about 5~15t per hour (depending on the characteristics of the material, the speed is also different, and fine powder may be slow).

3. Improved corporate image

The application of workshop automation and mechanization can improve the soft power of enterprises. Due to the improvement of work efficiency, when enterprises are still working overtime to catch up with orders, the factory using bag-feeding equipment has completed the order in advance and invested in the production of the next order. This way of working makes customers more willing to choose to cooperate with us.

4. Convenient for enterprise management

Unlike manual labor, mechanical equipment has many uncontrollable factors. For example, taking leave, low salary, job hopping, etc. But mechanical equipment will not. As long as daily maintenance is done, not only do you not have to worry about taking leave, job hopping, but you can also work all day without holidays.

5. Small footprint

The length of the bag-feeding vacuum packaging machine is 2510×1600×1600mm, while the length of the small stretch film equipment is 4500×800×1750mm, so compared with the stretch film vacuum packaging machine, the bag-feeding vacuum packaging machine saves space, and the enterprise does not have to worry about the problem of the factory building.

6. Low noise

The bag-feeding equipment is compactly designed. Since one device can meet the output of multiple small devices, it reduces the noise in the workshop and provides a good working environment for workers in the production process.

7. Automatic detection function

The bags can be recycled. The equipment is equipped with a detection function. If the bag is not filled, the equipment will not heat-seal the bag so that the bag can continue to be used without waste; and the detection function can also detect equipment failures. If a failure occurs, the cause of the failure can be displayed on the touch screen, saving time for the maintenance workers.

8. One machine can be used for multiple purposes

The bag-feeding vacuum packaging machine can be used for multiple purposes and package products of various specifications. Since the bag-feeding equipment uses motor control, it can adjust multiple stations at a time, so even if it packages products of various specifications, it does not take too much time to adjust the equipment.

Of course, no matter how advanced the equipment is, it is not perfect and will have shortcomings. For the bag-feeding vacuum packaging machine, there are the following shortcomings. You can learn about them and choose the equipment:

1. Limitation of packaging size

Although the bag-feeding vacuum packaging machine can achieve multiple uses, it has certain limitations on the bag size in terms of current domestic technology. The bag size cannot be too different. Generally, the bag size is 120-500mm and the width is 50-380mm. Bags that are too small or too large will affect the packaging effect.

2. Selection of feeding method

It is troublesome to change the feeding method of the bag-feeding vacuum packaging machine. It is generally not recommended that manufacturers equip a host with multiple feeding equipment. Therefore, when purchasing equipment, you must determine your own products. For example, granular products such as rice and dried fruits will choose electronic multi-head weighers for feeding; solid products such as pickles will choose screw-type feeding; for the marinated products series, choose a ring feeder; for similar products such as marinated eggs and quail eggs, you can use a dedicated fully automatic feeder.

3. Equipment maintenance

Whether it is a bag-feeding vacuum packaging machine or an ordinary vacuum packaging machine, if you want a long service life, you need to maintain and maintain the equipment. If the maintenance is timely, the general equipment service life is 8-10 years, or even longer, and it can be used for 5-8 years without maintenance; if the measurement accuracy is inaccurate, the equipment needs to be updated. Yudong's equipment transmission cam and vacuum air-tight disk achieve zero maintenance, and can guarantee a lifetime replacement.

With the changes of the times, enterprises will have higher and higher requirements for product packaging equipment, and manual operation will be replaced by intelligent, mechanized, and automated equipment. Enterprises will reduce labor input and realize unmanned workshops. This has become the key to the long-term development of enterprises. Therefore, bag-feeding vacuum packaging machines will become the preferred equipment for enterprises.

Other Packing Machine

Introduction to the performance characteristics of bag-feeding packaging machine

1. Easy to operate, PLC control is adopted, and it is equipped with a touch screen human-machine interface control syste......

A bag feeding structure of a bag feeding type packaging machine

The utility model discloses a belt feeding mechanism of a bag feeding type packaging machine, comprising a bag clampi......

What industries are bag-feeding packaging machines suitable for?

Technology is becoming more and more advanced, and the rapid development of science and technology has brought great con......

Fully automatic packaging machine

The packaging principle of the horizontal bag-feeding machine The horizontal bag-feeding packaging machine has been g......

Innovative plastic molding machines drive future manufacturing

It sounds very cumbersome to pack multiple materials into one bag after measuring them with different weights. The bag-f......

Development history of bag packaging machine

With the beginning of the industrial revolution, mechanical production gradually replaced the traditional manual product......