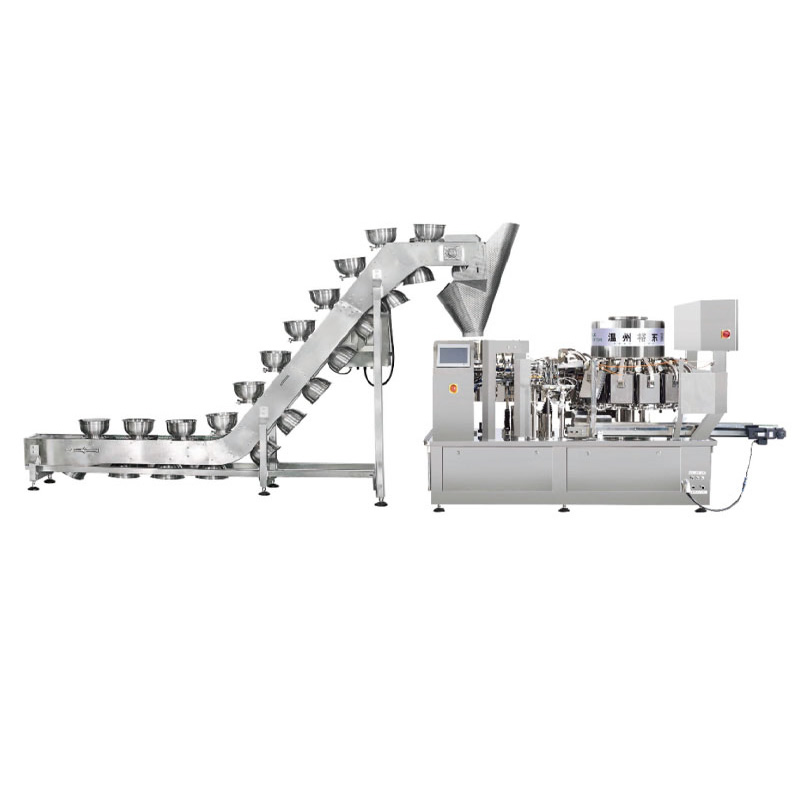

Automatic Bag Feeding Packaging Machine

Automatic Vacuum Premade Pouch Machine

Automatic Vacuum Packaging Machine

Premade Vacuum Packaging Machine

Fully Automatic Rotary Vacuum Packing Machine

Automatic Vacuum Food Packaging Machine

Automatic Vacuum Food Packaging Production Line

Fully Automatic Vertical Packing Machine

High Speed Vertical Form Fill Seal Machine

Fully Automatic Vertical Form Fill Seal Packaging Machine

Large Size Auto Vertical Packing Machine

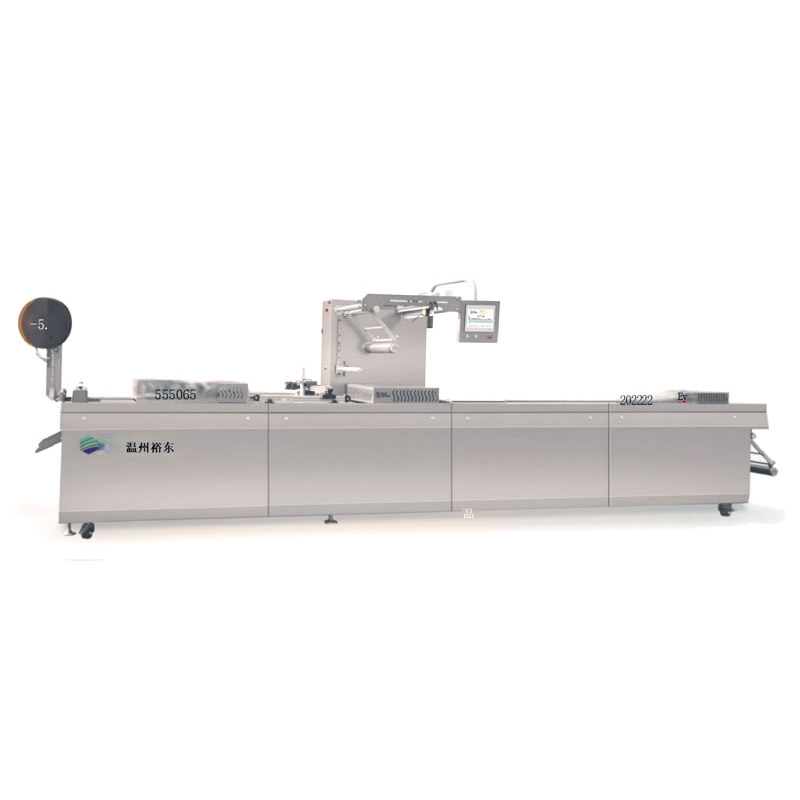

Automatic High-Speed Continuous Drawing Vacuum Packaging Machine

Automatic High-Speed Thermoforming Vacuum Packaging Machine

Fully automatic packaging machine

The packaging principle of the horizontal bag-feeding machine The horizontal bag-feeding packaging machine has been gradually integrated into the production activities without being aware of it. Its science and technology have brought production development, improved productivity, increased product profits, resource conservation, and reduced labor for many manufacturers, but do you really understand its basic structure? Next, Yudong Xiaobian will share the knowledge of the basic mechanism of the horizontal bag-feeding packaging machine with you

Horizontal bag-feeding packaging machine

1. The basic structure of the power element.

The power component is the power of the horizontal bag-feeding packaging machine, which is the kinetic energy generated by the motor, hydraulic pump and air compressor to promote the operation of the entire packaging machinery. The actual power required by the horizontal bag-feeding packaging machine is very small, generally between 1-3 kilowatts. Mechanical transmission consumes a lot of energy. In the design, rolling machinery with low friction loss should be used as much as possible to replace the connecting rod mechanism with large friction loss.

In the production of modern bag packaging, the horizontal bag-feeding packaging machine is the darling of the packaging market. This packaging machine simplifies the packaging production process, saves labor, improves labor productivity, and reduces production costs and adaptability.

2. Basic structure of metering device

Measuring is an important part of quantitative packaging of items. Items with different shapes have different packaging methods and specifications; even for the same type of materials, various specifications of packaging need to be sold to meet the requirements of different consumers. This makes the metering process complicated. Because there are many types of packaged items, different properties and values, different packaging methods, metering work cannot be divided, and the measuring device will also vary depending on the type, nature, value and measurement accuracy requirements of the measured items.

Other Packing Machine

Introduction to the performance characteristics of bag-feeding packaging machine

1. Easy to operate, PLC control is adopted, and it is equipped with a touch screen human-machine interface control syste......

A bag feeding structure of a bag feeding type packaging machine

The utility model discloses a belt feeding mechanism of a bag feeding type packaging machine, comprising a bag clampi......

Professional automatic thermoforming machine manufacturer

The bag-feeding vacuum packaging machine was born to help enterprises solve the problems of labor shortage and managemen......

What industries are bag-feeding packaging machines suitable for?

Technology is becoming more and more advanced, and the rapid development of science and technology has brought great con......

Innovative plastic molding machines drive future manufacturing

It sounds very cumbersome to pack multiple materials into one bag after measuring them with different weights. The bag-f......

Development history of bag packaging machine

With the beginning of the industrial revolution, mechanical production gradually replaced the traditional manual product......